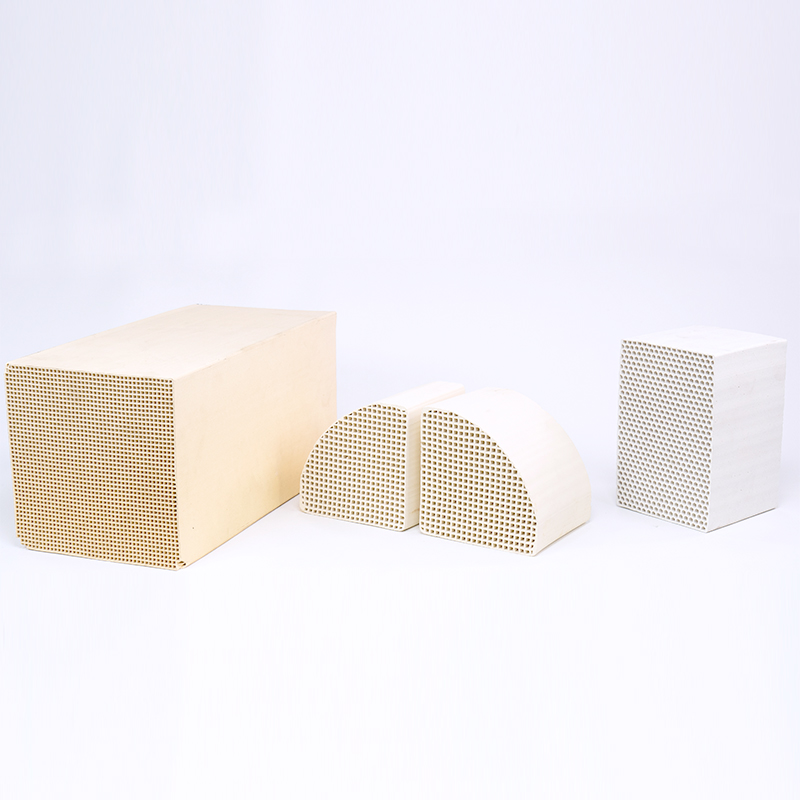

RTO – Heat Exchange Honeycomb Ceramic

Ọrụ

1.Reduce thermal ọnwụ nke iyuzucha gas, na melite arụmọrụ nke mmanụ ụgbọala na-azọpụta ike dị ka.

2.Enhance ọkụ okpomọkụ dabeere na tiori, melite ikuku ọkụ, izute elu okpomọkụ nke thermal ngwá na-amụba ala calorific uru mmanụ ụgbọala, karịsịa ngwa nso nke gbawara ọkụ, melite arụmọrụ nke calorific uru mmanụ ụgbọala na-ebelata umu anwuru si ala calorific uru coal gas.

3.Mmelite okwu nke mgbanwe okpomọkụ na hearths, na-amụba mmepụta nke ngwá ọrụ, welie àgwà nke ngwaahịa na belata reinvesting na ngwá.

4. Belata ikuku ikuku nke akụrụngwa ọkụ, belata mmetọ ikuku ma melite gburugburu ebe obibi.

Njirimara

Ihe e ji mara nke ceramic regenerator nke mmanụ aṅụ dị ka ndị a: ha nwere mgbasawanye ọkụ dị ala, ikike okpomọkụ dị elu, ebe dị elu dị elu, nkwụsị nrụgide dị ala, nkwụsị ọkụ dị ala, ezigbo ikuku okpomọkụ, nkwụsị ọkụ ọkụ na ọtụtụ ndị ọzọ. Yabụ, na ụlọ ọrụ ọla na kemịkalụ, a na-eji ya dị ka HTAC, ebe anyị na-ejikọta imegharị okpomọkụ nke ihe ndị a na-emepụta, ọkụ ọkụ dị elu nke ọma yana ibelata NOx. Ọ na-aghọ ezigbo nchekwa ike ma na-ebelata Nox.

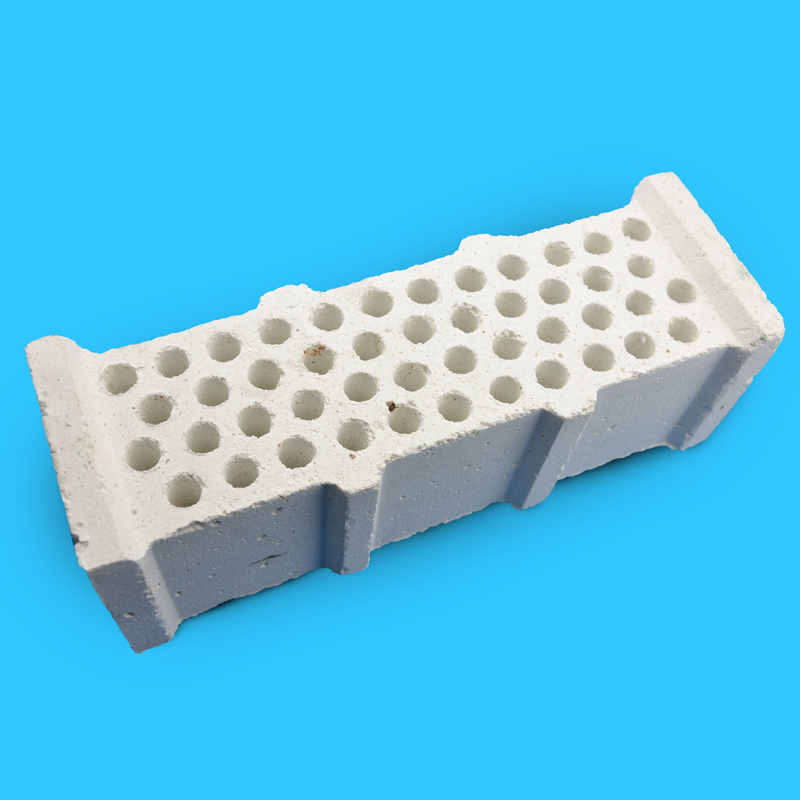

Akụrụngwa: Alumina, Obere Alumina, Cordierite, Okwú Cordierite, Mullite, Corundum Mullite na ndị ọzọ

Ngwa

Seramiiki mmanụ aṅụ bụ isi ihe na isi ihe na-echekwa okpomọkụ dị elu teknụzụ combustion (teknụzụ HTAC). A na-eji ya eme ihe n'ụdị ọkụ ọkụ dị iche iche na-agbanye ígwè, ọkụ ọkụ na-eje ije, ọkụ ọgwụgwọ okpomọkụ, ọkụ ọkụ ọkụ, ọkụ na-agbaze, ladle / tundish roasters, ite ọkụ, radiant tube burners, na ụdị mgbịrịgba na ụlọ ọrụ ígwè ígwè. Igwe ọkụ, ọkụ ọkụ ọkụ ọkụ ikuku ọkụ; ọkụ seramiiki dị iche iche na ọkụ iko dị iche iche na ụlọ ọrụ ihe owuwu ụlọ; Igwe ọkụ tubular dị iche iche, ọkụ na-agbawa ọkụ na ọkụ ndị ọzọ na-emepụta ihe na ụlọ ọrụ petrochemical.

Nkọwapụta

100x100x100,100x150x150,150x150x150,150x150x300mm na ndị ọzọ

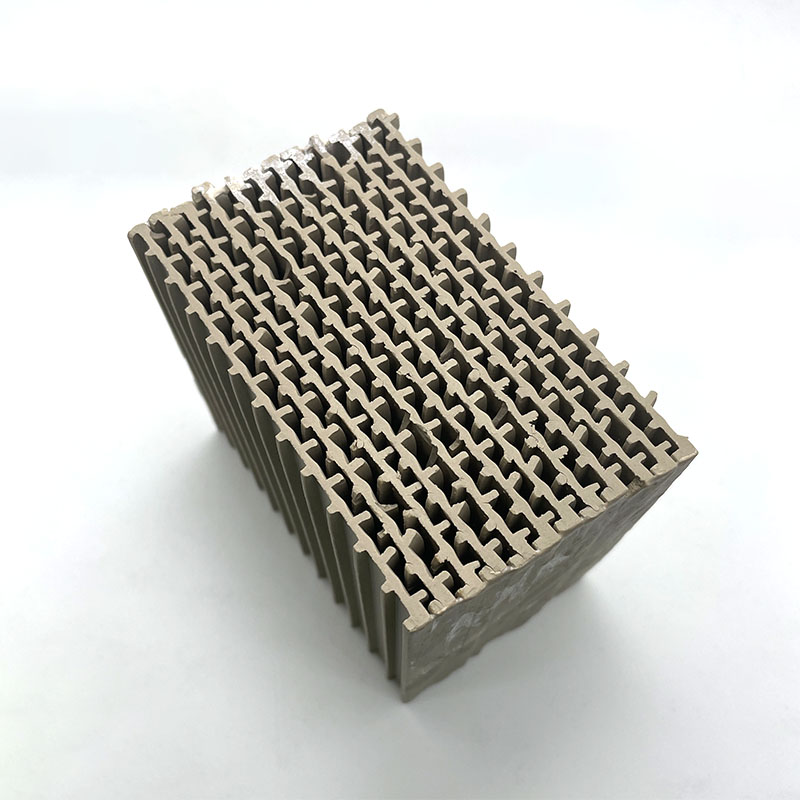

Ọnụ oghere: 25x25, 40x40,43x43,50x50,60x60 na ndị ọzọ

Akụkụ

| Akụkụ (mm) | Selụ (N × N) | Njupụta cell (CPSI) | Obosara ọwa (mm) | Mgbidi dị n'ime (mm) | Ngalaba Cross efu (%) |

| 150×150×300 | 20×20 | 11 | 6.00 | 1.35 | 64 |

| 150×150×300 | 25×25 | 18 | 4.90 | 1.00 | 67 |

| 150×150×300 | 32×32 | 33 | 3.70 | 0.90 | 63 |

| 150×150×300 | 40×40 | 46 | 3.00 | 0.70 | 64 |

| 150×150×300 | 43×43 | 50 | 2.80 | 0.65 | 64 |

| 150×150×300 | 50×50 | 72 | 2.40 | 0.60 | 61 |

| 150×150×300 | 59×59 | 100 | 2.10 | 0.43 | 68 |

Ngwakọta kemịkalụ

| Ihe | Cordierite | Mulite | Alumina Poselin | Alumina poselin dị elu | Corundum |

| Al2O3 | 33 | 65 | 54 | 67 | 72 |

| SiO2 | 58 | 30 | 39 | 23 | 22 |

| MgO | 7.5 | <1 | 3.3 | 1.7 | <1 |

| Ndị ọzọ | 1.5 | 14 | 3.7 | 8.3 | 5 |

Njirimara anụ ahụ

| Ihe | Cordierite (Porous) | Mulite | Alumina Poselin | Alumina poselin dị elu | Corundum | |

| Njupụta (g/cm3) | 1.8 | 2.0 | 1.9 | 2.2 | 2.5 | |

| Mmụba mmiri (%) | 23 | 18 | 20 | 13 | 12 | |

| Ọnụọgụ nke Mgbasa ọkụ (× 10-6K-1) (20 ~ 800 ℃) | ≤3.0 | ≤6.0 | ≤6.3 | ≤6.0 | ≤8.0 | |

| Okpomọkụ akọwapụtara (J/Kg.K) (20 ~ 1000 ℃) | 750-900 | 1100-1300 | 850-1100 | 1000-1300 | 1300-1400 | |

| Nrụpụta okpomọkụ (W/mk) (20 ~ 1000 ℃) | 1.3-1.5 | 1.5-2.3 | 1.0-2.0 | 1.5-2.3 | 5–10 | |

| Oke. Okpomọkụ na-arụ ọrụ (℃) | 1200 | 1400 | 1300 | 1400 | 1650 | |

| Ike ịkụpịa axial (MPa) | Akọrọ | ≥11 | ≥20 | ≥11 | ≥22 | ≥25 |

| Nmikpu | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | |